Our Products

Our Products

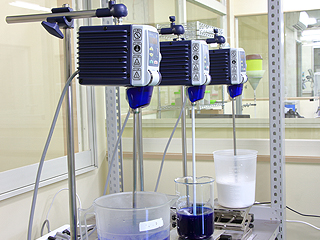

The general term for paints used to coat metal molds and parts that come into contact with molten metal is "coatings". At ADELE, we have a separate term, facing, for paints used to coat the molds used for gravity die casting (GDC) and low pressure die casting (LPDC) where they come into contact with the molten metal, mold cavity surfaces, and gating system surfaces (riser, runners).

We use the term, coating, for the paints used to coat surfaces other than the molds, such as ladles, dippers, unstructured refractories, Riser Tube, and Surface Detecting Sensors.

Facings

Application: Metal molds

ADELE's facings have the following main functions.

- Protection of mold surfaces

- Prevention of solidification and maintenance of temperature until mold is completely filled with molten metal

- Venting to absorb trapped air, etc. during the pour

- Adjustment of solidification speed to create directed solidification

- Lubrication for mold release

- Surface roughness adjustment for clean casting surfaces

- Prevention of molten metal adhesion

Examples of Main Products:

- Automobile and motorcycle parts (aluminum wheels, cylinder heads, pistons, frames, housings, and many others)

- Others (robot parts, medical parts, semiconductor manufacturing equipment parts, outboard motors, cooking utensils, and many others)

Product Types

| Mold Cavity |

|

||||

|---|---|---|---|---|---|

| Gating System |

|

||||

| Galling/Surface Roughness Prevention Improved Mold Removability |

|

Coatings

Applications: Ladles, dippers, spout, unstructured refractories, Riser Tube, and Surface Detecting Sensor

ADELE's coatings, other than facings, have the following main functions.

- Prevention of erosion

- Prevention of molten metal adhesion

- Electrically conductive

Product Types

| Prevention of dissolved loss |

|

||

|---|---|---|---|

| Improved pour stop |

|

||

| Improved conductivity + pour stop |

|

Please contact our sales staff for advice about selecting the best product for your purposes.